The main application of laser cutting is the production of advertising and information products.

The main activities of the cutting center at the OliveAds Construction & Advertising include: laser beam cutting, plasma arc cutting, and milling. We also offer engraving and 3D cutting, performed on specialized equipment. Our machines cut and process various materials, such as: plywood, polycarbonate, wood, plexiglass, brass, aluminum, polystyrene, PVC, PET and other flat-sheet materials. The operational field of the machines allows processing materials with a length of more than 6 meters and the width of up to 2 meters.

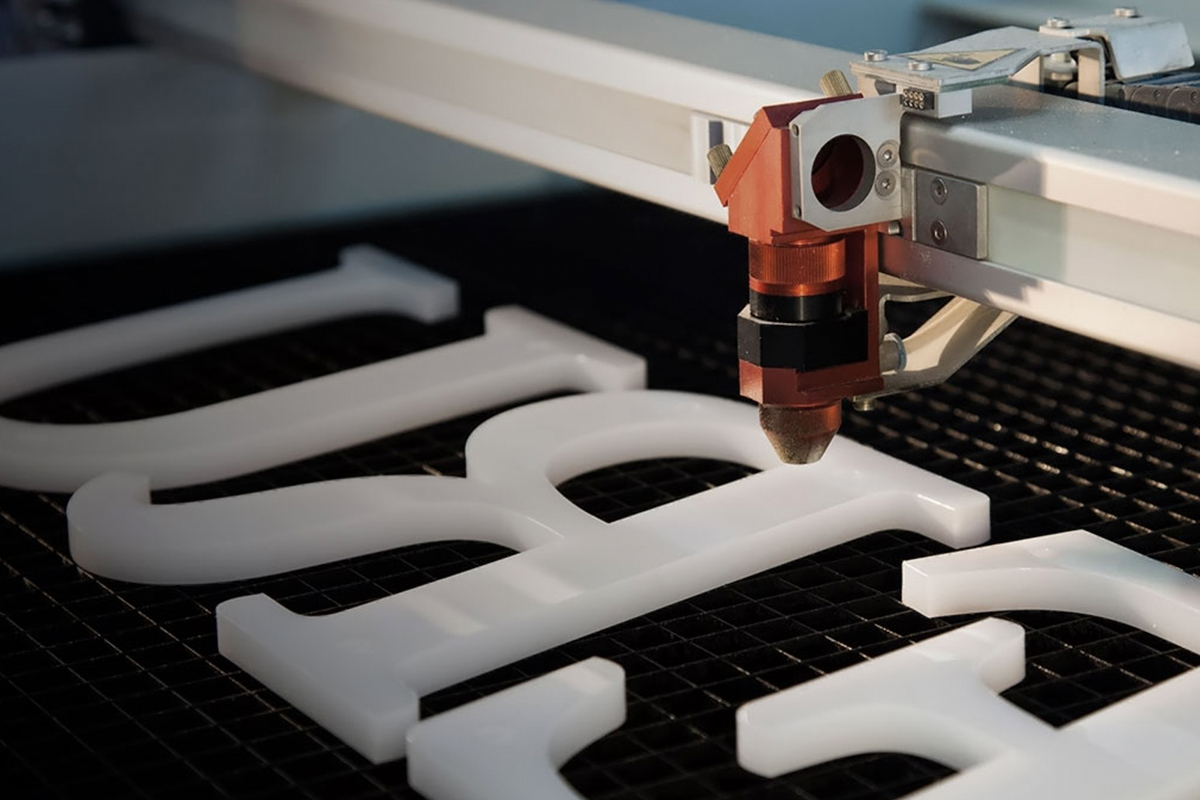

Laser beam cutting

The main application of laser cutting is the production of advertising and information products. Laser beam cutting is widely used in the creation of souvenir business products, as well as in the design of lightboxes, 3D and luminous letters to decorate advertising signboards, showcases, entrances to sales rooms and lobbies of shopping centers.

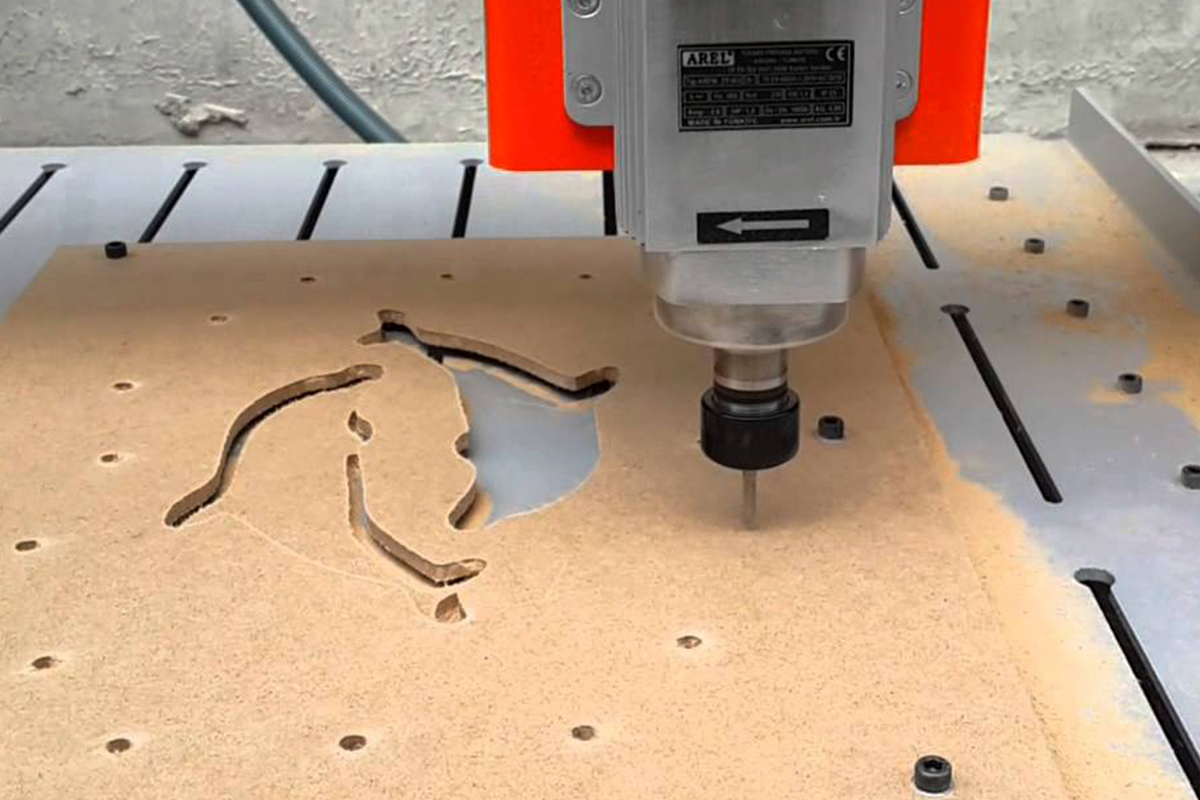

Milling

Milling (mechanical processing of the material surface by cutting) in the field of outdoor advertising. For the production of advertising signboards, 3D letters, lightboxes, panels of various shapes and sizes. At the same time, it is possible to process a large number of different types of materials: plastics (plexiglass, acrylic, PVC, etc.), any types of wood, composite panels, plywood, stone, non-ferrous metals, polycarbonate and much more. The technology allows processing materials with a thickness of 15 mm.

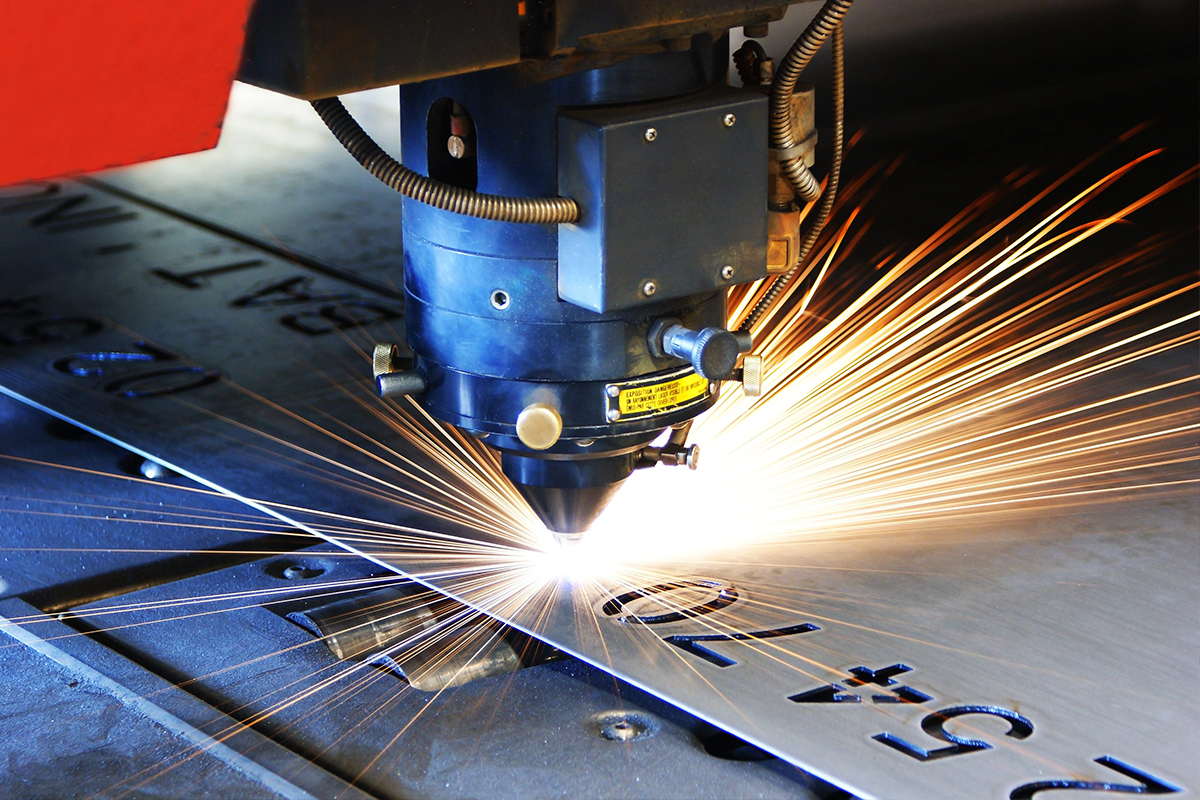

Plasma arc cutting

Plasma arc cutting is a cost-conscious metal processing process used in the production of advertising structures. It makes it possible to obtain finished products with no need for further processing. This method is applicable for the absolute majority of metals, including steel, cast iron, bronze, copper, brass, titanium, aluminum and their alloys. The use of CNC and specific programs allows you to manufacture flat parts of any complexity: processing of any metal with a thickness of up to 200 mm, performing work on a CNC machine discounts the error probability, it has no restrictions on the product shape, metal carving, performing straight and curved cuts, the ability to make holes, including complex shapes, accurate and qualitative performance of the product, high speed and accuracy of work, the cost of the product is lower than with artistic forging.

Plotter cutting

Plotter cutting is a technology allowing cutting through the subsurface, carving, perforating, cutting through the material along the image contour from various materials, for example, self-adhesive film. Materials for plotter cutting can be: vinyl film, paper, cardboard, plastic, metal, magnetic vinyl, fabric, self-adhesive paper.